The best way to predict the future is to create it.

Foundry Design

We can design all elements of a lost foam foundry

Foundry Engineering

Expertise in all aspects of Lost Foam Engineering

Foundry planning and realization services

We can make it happen.

More than 40 Years of Experience

With more than 40 years of experience and expertise in the foundry industry - especially Lost Foam Technology - we offer dedicated foundry solutions for aluminum, iron, steel and all other castable metals.

A Qualified Team

We have team of highly qualified experts with proven track records in management and engineering positions. Their expertise covers a wide range of functions in the cast metal industry, procurement, foundry design, project management and casting quality improvement.

Turnkey Contract

Our focus is totally on enabling our clients to meet their objectives. Whether for new (greenfield) foundries, an expansion, modernization or installation of a single equipment project in your existing foundries, we can help you with project management or turn-key contracting of your project. This will allow our clients to concentrate on their core activity: producing castings.

Our latest project

"The Turn-Key Plant"

Customer Location: the Silk Road-Hub – Horgos

How we machine and subassembly the components

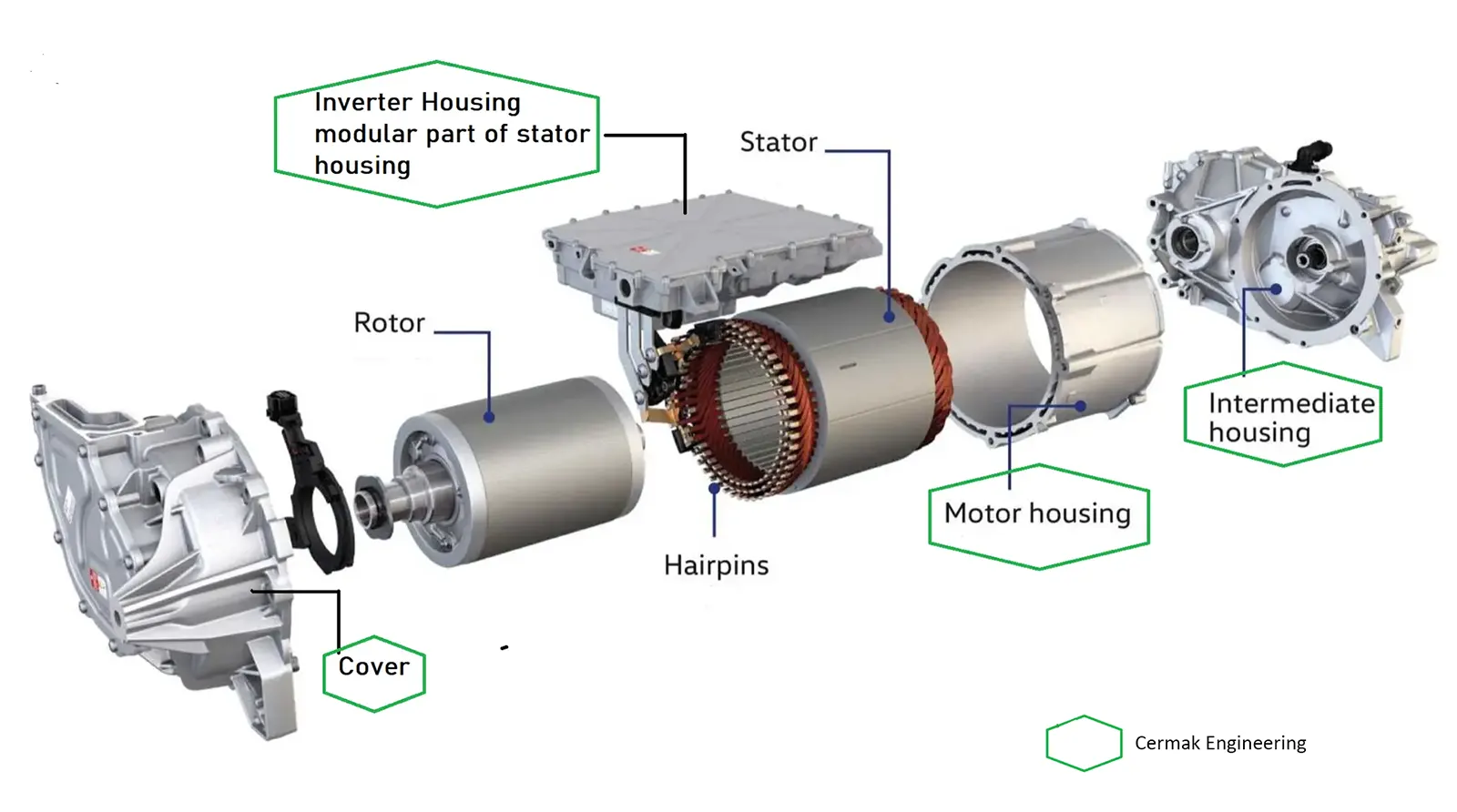

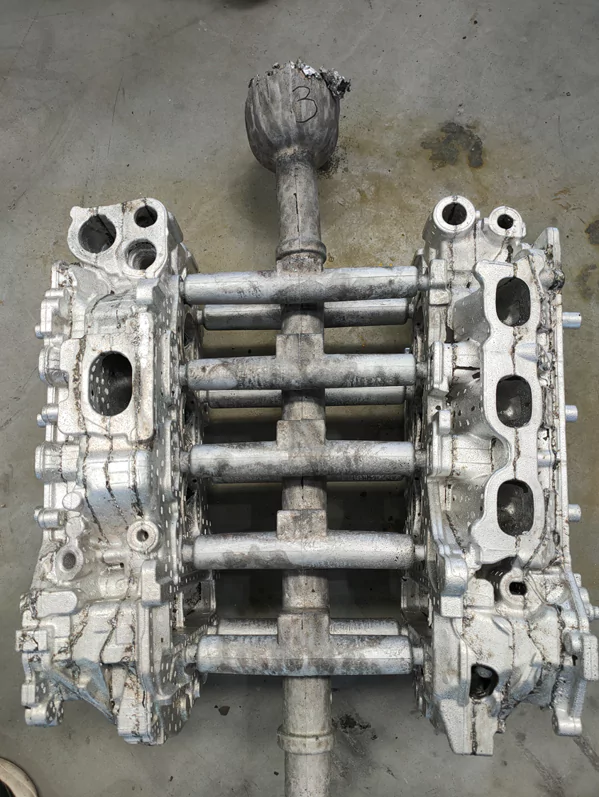

Second casting in pilot phase:

Third casting in pilot phase:

Scope of our Work

1. Technology and compatibility

Technological equipment was designed by our team:

- KCE GmbH in Germany.

- Manufactured by experienced (20 years co-partner of GF and Disa) privately owned Mechanical engineering and manufacturing company Ma ltd.

- All Automation including Robotics was designed by Siemens and ABB trained and experienced (10+ years working as integrator for ABB and Siemens) Kongs Team. Both companies are bound to Cermak E-Tech-Horgos with long term service contracts.

2. Equipment and design

In line of European automotive specifications and Chinese safety codes.

Selected suppliers :

Siemens, ABB-Robotics, Festo, Norgren, Parker, Bosch, Gemue, Spirax, Sommer, Shott

3. Projection of plant capacity

- Phase I: 100 Flask per hour ( 1.000.000 cylinder heads / a with 2-on cluster)

- Phase II: 100 Flask per hour ( 1.000.000 head’s )

- Phase III: 100 Flask per hour ( 1.000.000 head’s)

4. Raw materials and consumables

- EPS – Styrochem and Taiwan cup bead producer

- Coating- ASK – Germany and ASK China

- Hot melt glue – Ruderer/Fueller

5. Software

- For mechanical design and tooling

- Pro-Engineer

- E-plan for controls

6. Quality management

Quality Handbook is ready for audit, ISO 9004 and …….application on the way.

7. Remote process

- Monitor/control

- All control have SCADA capabilities, remote monitoring and sharing HMI screen’s.

- Virtual auditing „walk through plant“ will be realized in 2022

8. Support from outside

- MOU with IFAM institute was signed, first license for cast components is in process

- Expert remote team is set up to support with Process and product control

- Close cooperation and consulting service with Karel Cermak Engineering GmbH is operational, Import and export department is experienced.

Product technical evaluation, economics, process capability, plant capacity, equipment and buildings requirement.

Product capability check

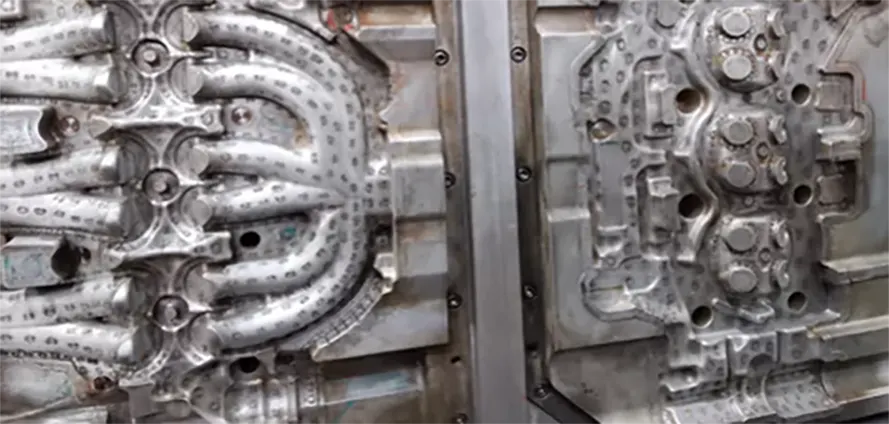

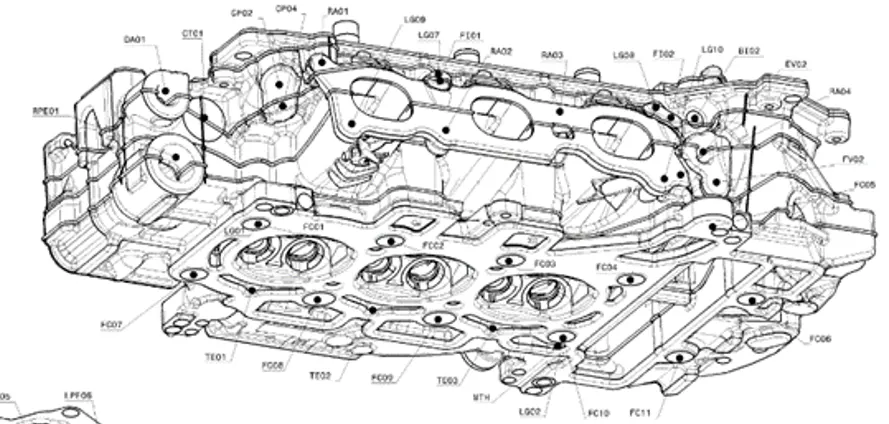

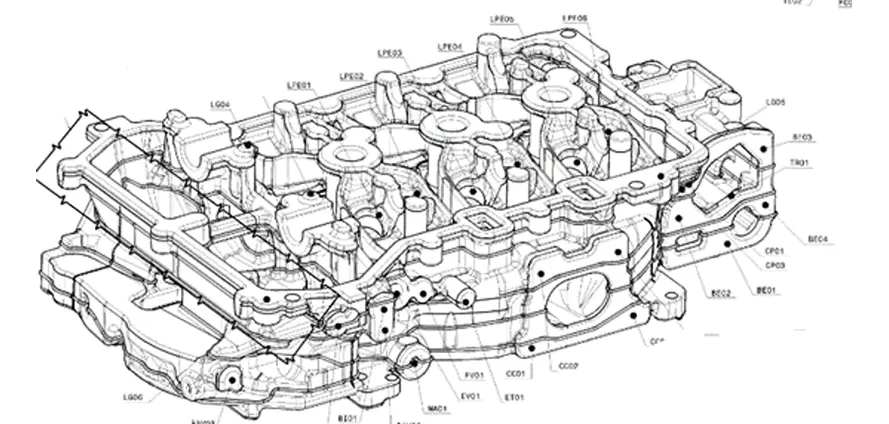

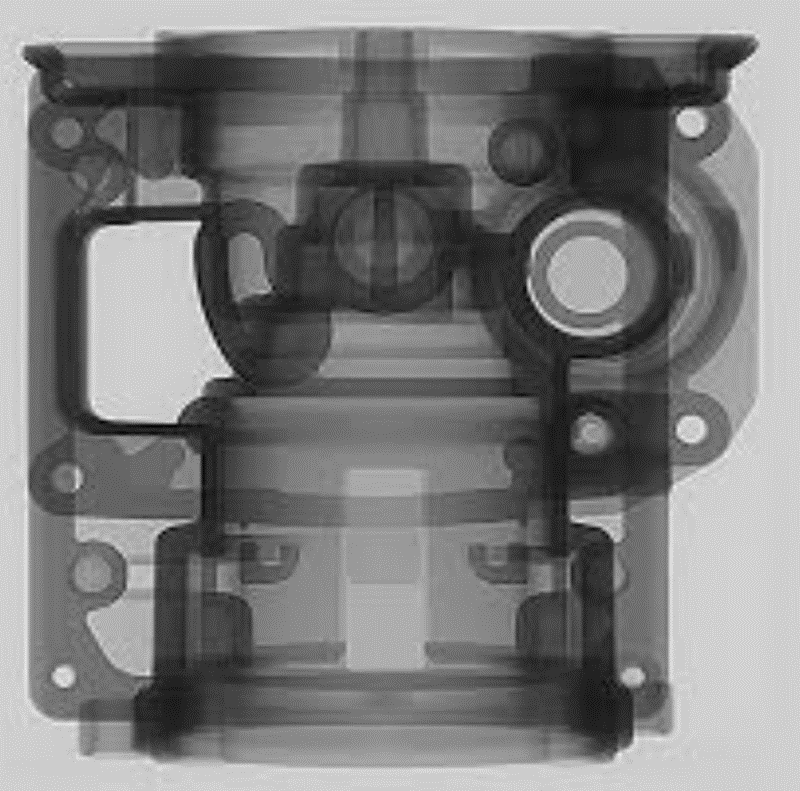

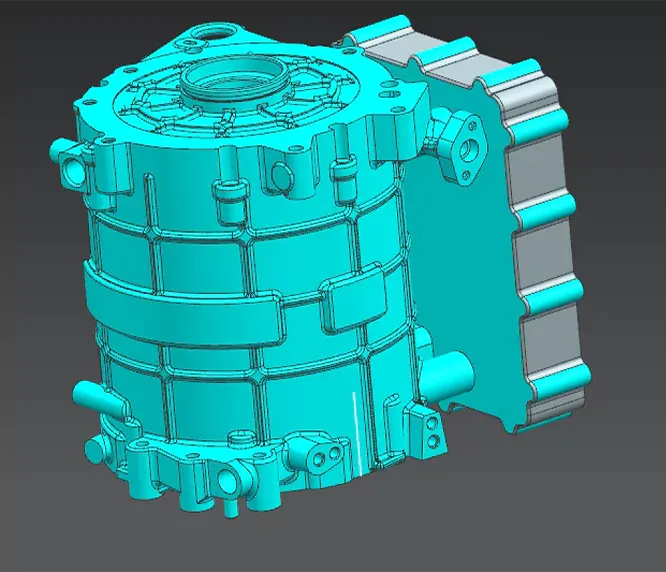

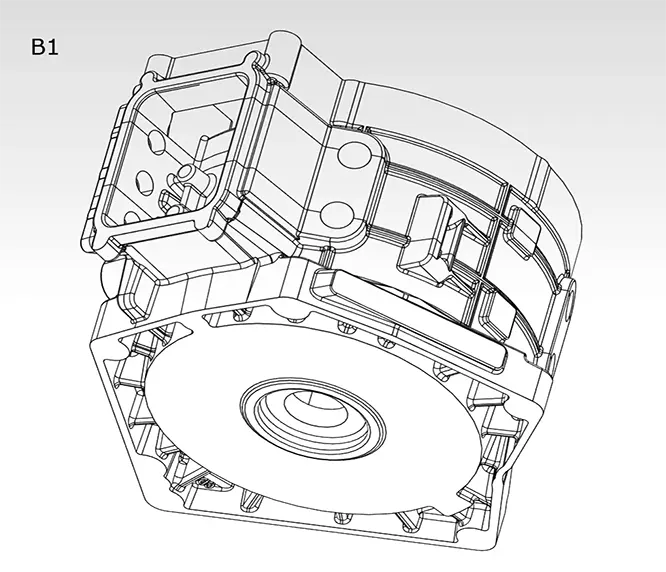

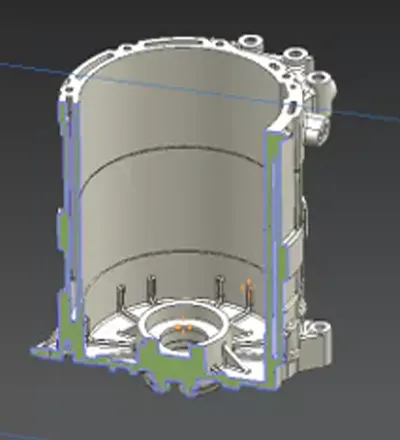

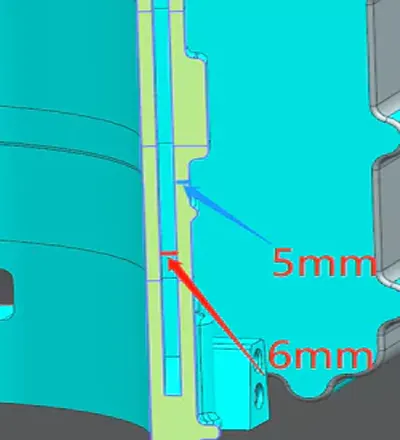

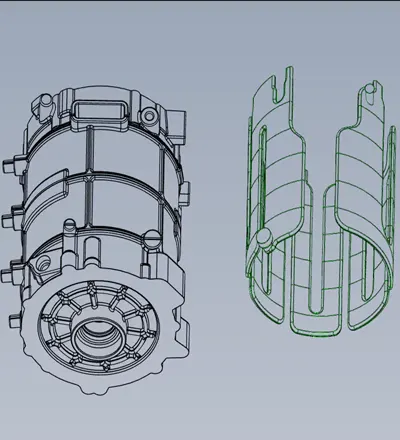

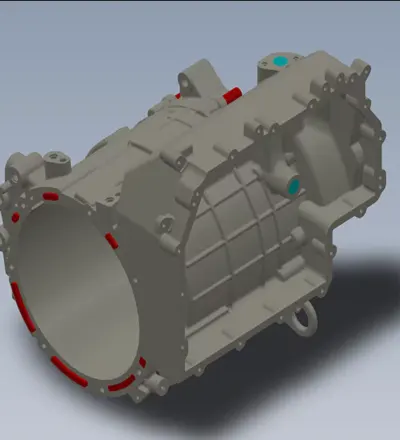

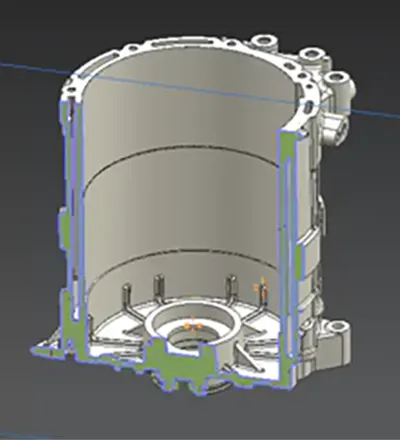

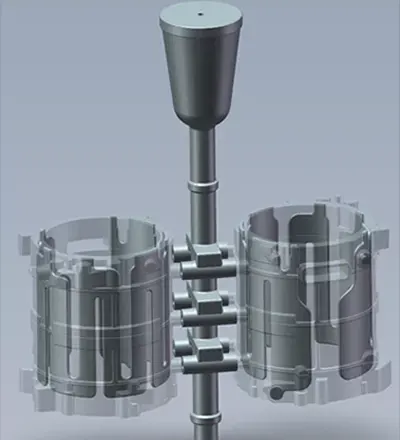

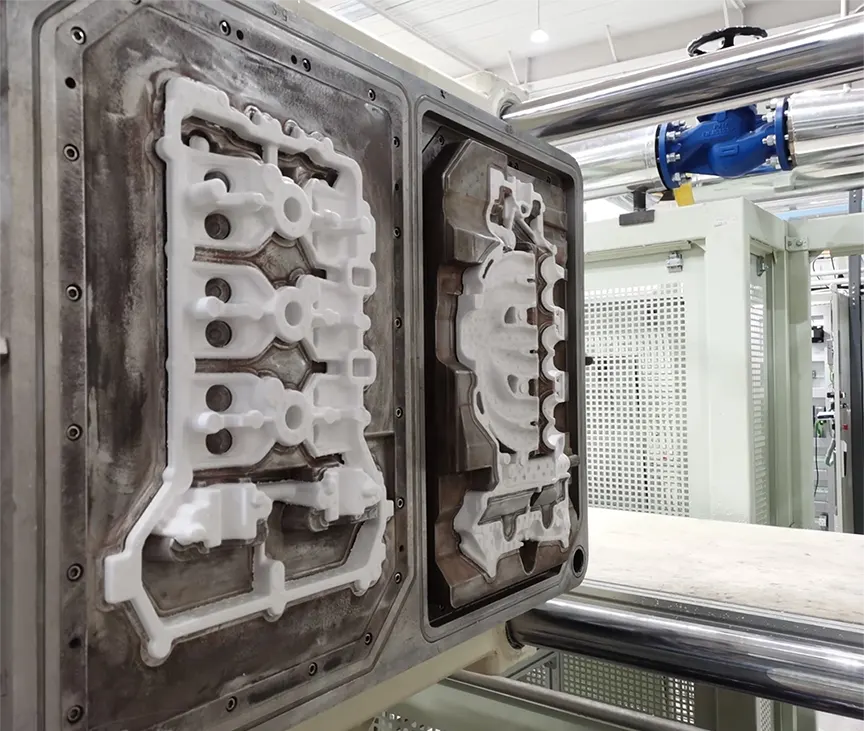

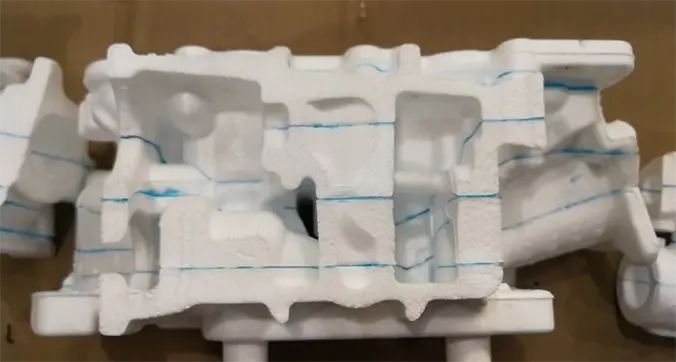

Design of casting, adoption to LF –Process, 3D animation helped to optimal parting geometry and feasible foam slices and cluster arrangements

A deeper Look

Design of casting, adoption to LF –Process, 3D animation helped to optimal parting geometry and feasible foam slices and cluster arrangements

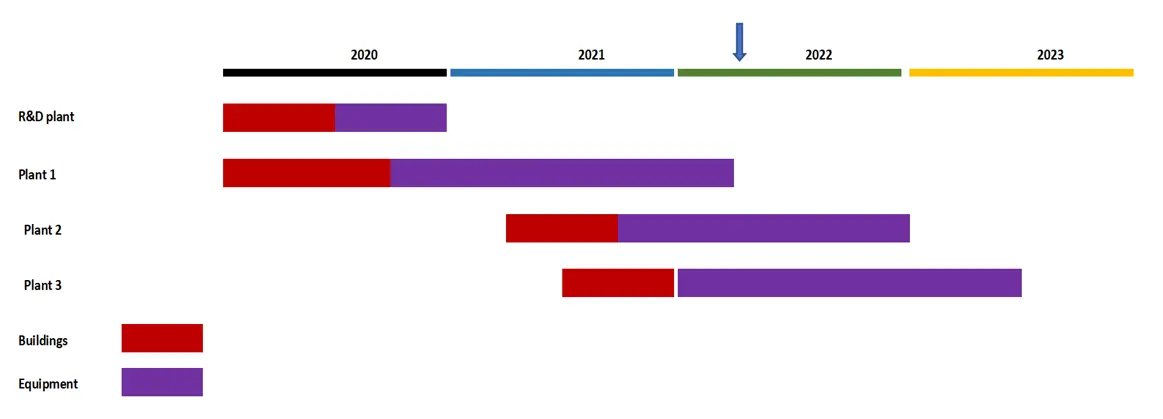

Ramp up Plan 2024 - 2028

- Ground Breaking in February 2019

- 180.000m2 under the roof in Phases I-IV, Land 420000m2

- Pre-production Order of 10.000 Casting started 01/2021

- First production ready castings 03/2022

Plant Projected Capacity (Casting weight depending factor) in:

- Phase I - 2022-2026 ramp up to 13,250 t/a

- Phase I - 2023-2027 ramp up to 26,500 t/a

- Phase I - 2024-2028 ramp up to 39,750 t/a

- Total: 2028 ramp up to 79,500 t/a

The Reached Timing Target

Pre-Expansion and Bead Storage

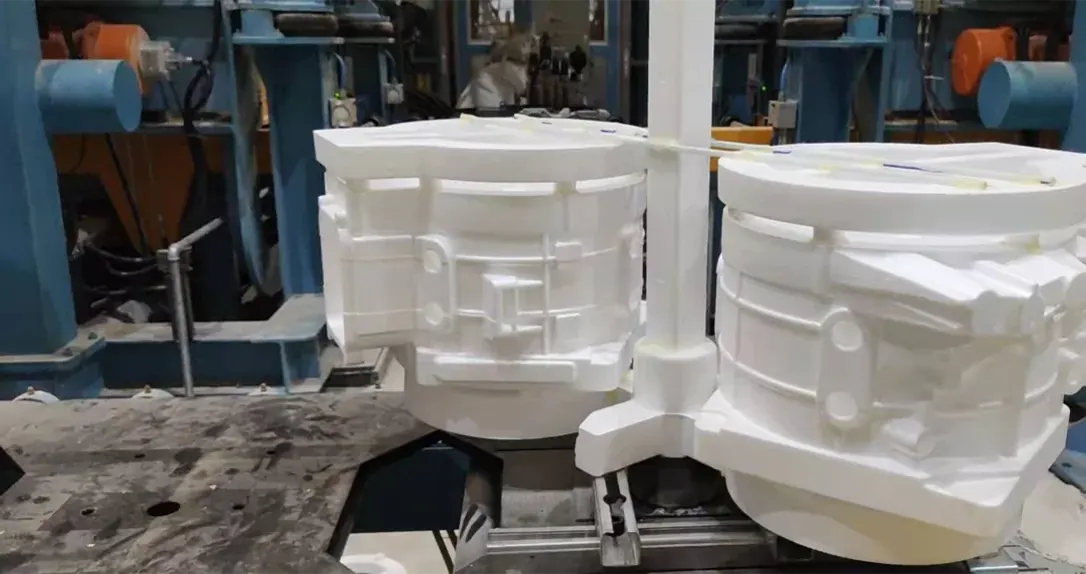

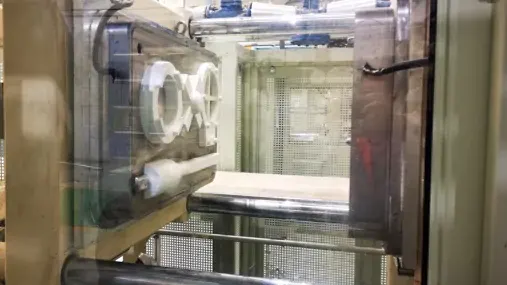

Molding Machines

Molding Machines

Foam Slices 1 and 2 cylinder head and down sprue gating

Pattern Slices transport / Mobile storage stabilization oven

CNC Gluing with cold glue in prototyping Phase

Hot Melt Gluing Department

Automatic hot melt gluing of cylinder heady

Automatic hot melt gluing of cylinder head

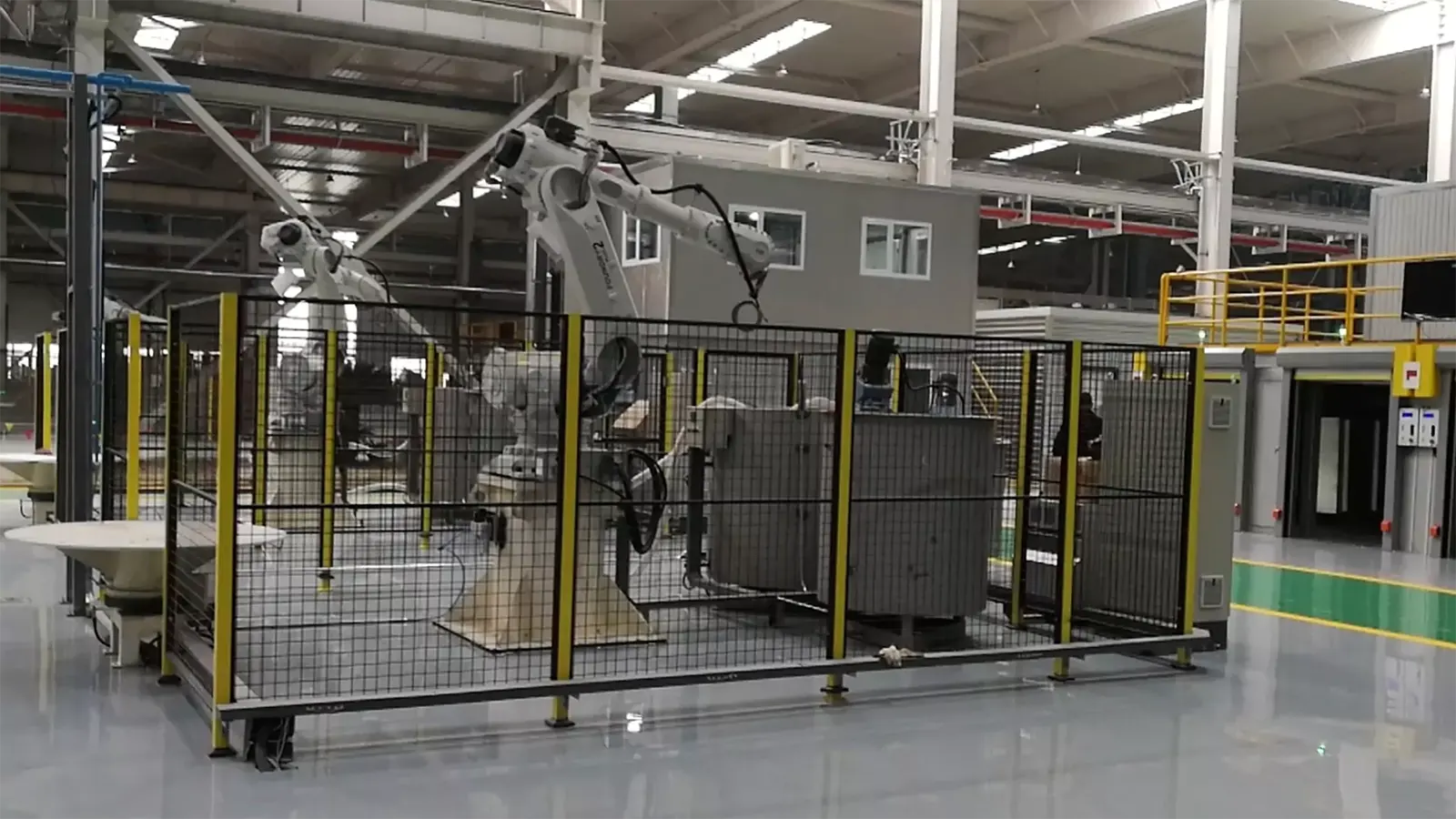

Robotic coating cells, climatized drying oven

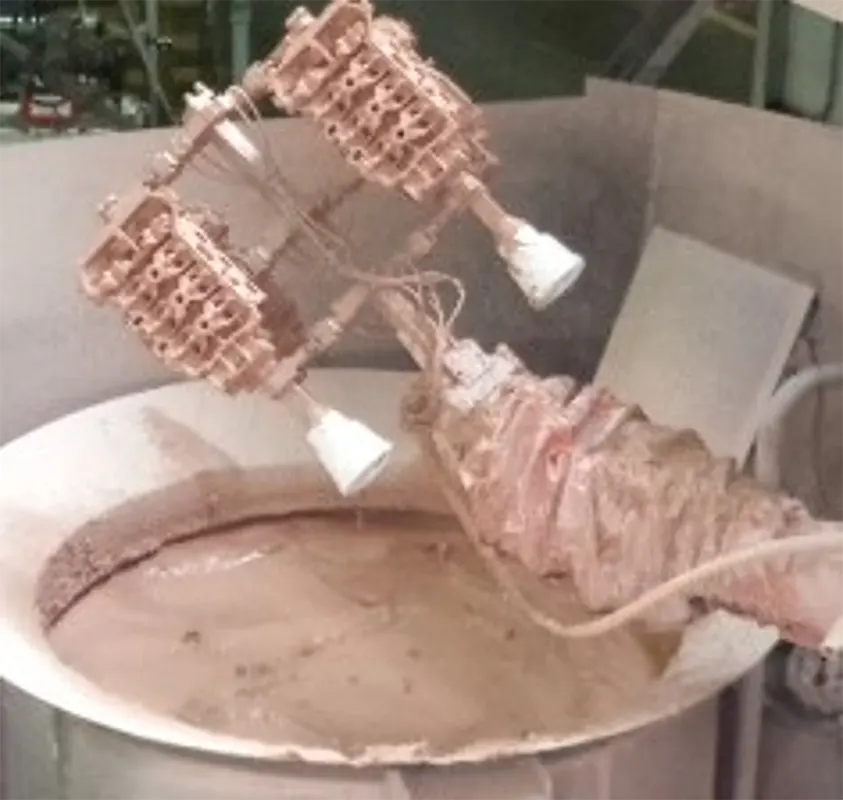

Robotic Coated Cluster

Robotic Coated Cluster

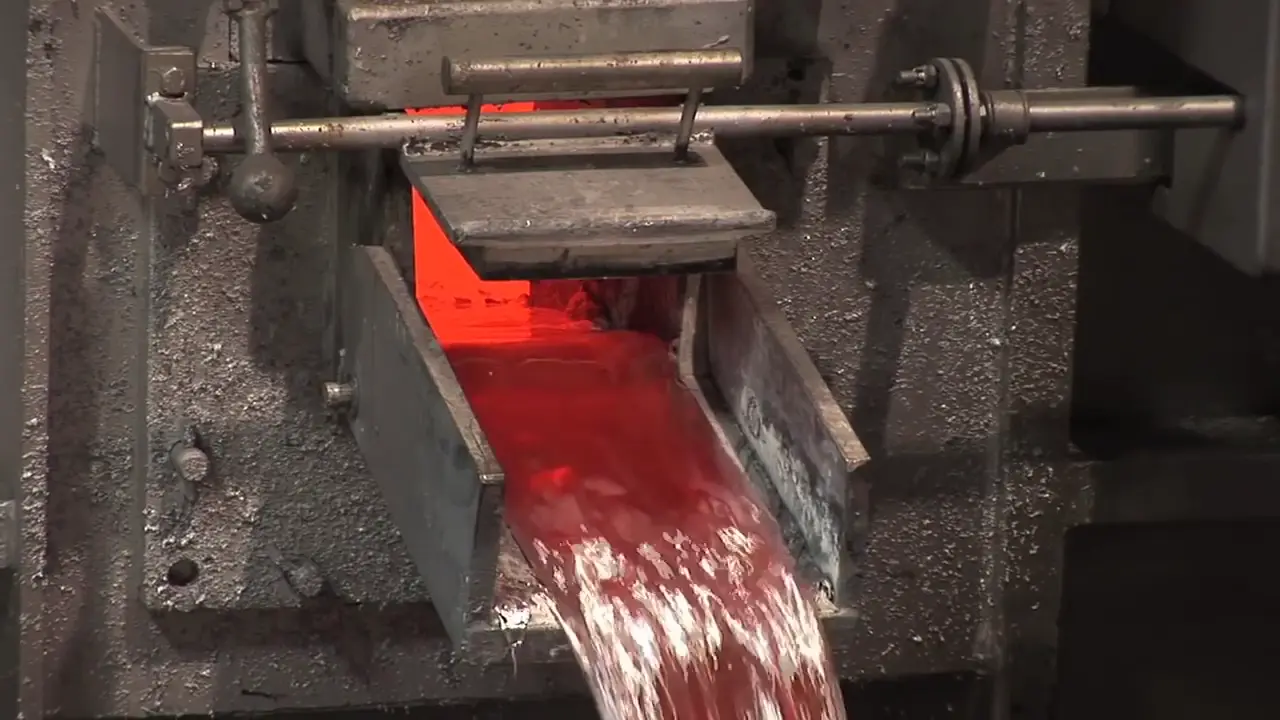

Cluster Insertion, sandfill & compact & pour

Cluster Insertion, sandfill & compact & pour

Melting furnace, 2,5 to/h, gas fired

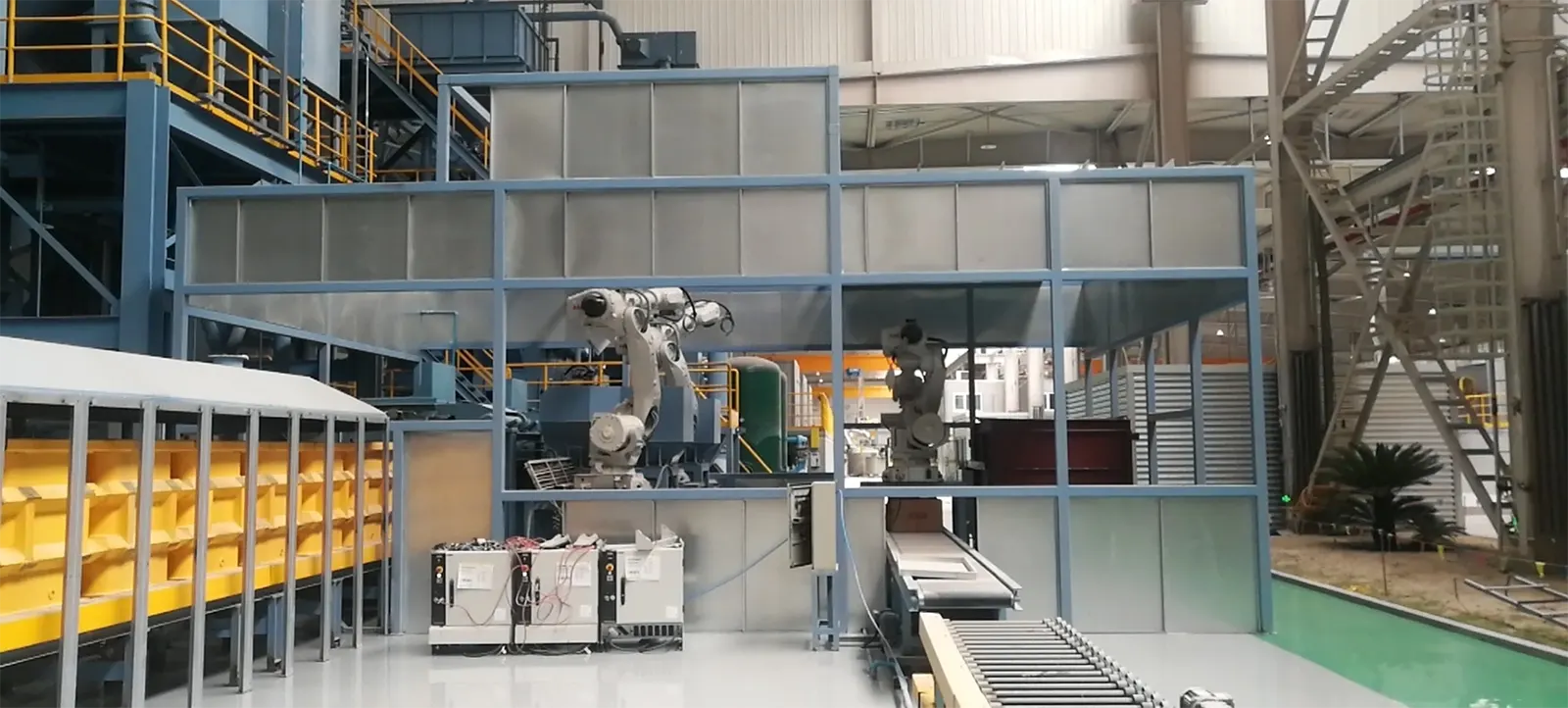

Robotic pouring, metal holding & treating furnace

Cooling track, dump, extraction robot, quenching

Sand recycle tower, screen, cool, feed back loop

The dump sand, extract cast cluster, sent sand into treatment loop

First Batch of good looking consecutive poured cyclinder heads

Heat treament T6/T7 installed and commissioned

Heat treament T6/T7 installed and commissioned

Shot blast, GF style rotary table

Magical Lost Foam, We turn 200g into 24.000g

Are you interested as our customer or our partner?